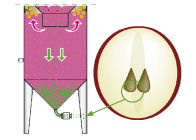

1. FILLING

AND CAVITY SATURATION

Filling can be performed either from above, or from the total discharge valve or from the partial discharge valve.

During the rising of the must, the cavity between the outer casing and the funnel diaphragm remains empty because the air, unable to escape through the closed bypass, prevents the cavity from being filled. The grape marcs accumulate on the surface to create the cap.

The carbon dioxide produced by the fermentation process quickly takes the place of the air in the cavity.

As soon as the environment is saturated, the exceeding gas goes out by overflowing and since it is under pressure it creates large bubbles through the diaphragm neck, resulting in a constant restirring of the grape marcs that will always be saturated with the liquid and well shelled. Such restirring causes the fall of the grape seeds to the bottom by gravity.

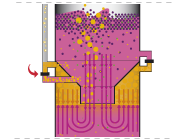

How does it work?

How does it work?