pi = H(T) xi

"The amount of a given gas that dissolves in a given type and volume of liquid is directly proportional to the partial pressure of that gas in equilibrium with that liquid."

Home > Metodo Ganimede® > Use of Technical Gas

Use of Technical Gas

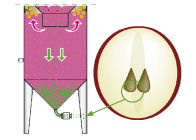

Use of Technical GasThe following diagram shows how in traditional systems the gases injected go quickly through the liquid, without being able to remain in contact with it for the right amount of time, dissolving very soon in the environment and affecting only a limited part of the mass, which by not exerting any pressure on the gas itself, cannot mix with it.

pi = H(T) xi

"The amount of a given gas that dissolves in a given type and volume of liquid is directly proportional to the partial pressure of that gas in equilibrium with that liquid."

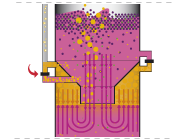

Only by using Ganimede® technical gases injected through a special valve can remain inside the cavity in contact with the liquid mass as long as we like, under pressure generated by the thrust of the liquid mass (0.2/0.4 bar) and in close contact with the large contact surface between gas and must (80/85%). In traditional systems, instead, all gases injected go through the liquid quickly, without being able to stay in contact with it for sufficient time, dispersing very quickly in the environment and affecting only a limited portion of the mass, which, by not exerting any pressure on the gas itself, fail to mix with it. Moreover, let's not even mention certain practices concerning an indiscriminate and dangerous exposure of the liquid to the external environment, too often empirically defined as "oxygenation of the mass", without the possibility of implementing a scientific management process or adequately monitor its effects.

Only by using Ganimede® fermenters we can use a scientifically known physical principle known as "Henry's Law". The technical gas injected below the diaphragm, under pressure from the liquid above, will exercise on the liquid itself a pressure equal to the one it has received.

For this reason, the gas will dissolve in the liquid mixing with it deeply, according to controllable and repeatable parameters that allow the winemaker to perform true management of the process with no room for improvisation and surprises. Moreover, at the opening of the bypass, the entire mass of gas that was under pressure up until that moment, is released on the grape marc cap with a stirring effect amplified by the phenomenon of decompression created thanks to the sudden decrease in pressure caused by the opening of the bypass itself. This causes the formation of many bubbles (a phenomenon readily identifiable at the opening of bottles of sparkling wine).

An EXCLUSIVE Ganimede® product designed for White and Rosé wines capable of enhancing aromas and reducing the use of sulphur dioxide in order to produce healthier wines!

go »

Metodo Ganimede® is the only fermenter in the world that allows winemakers to exclude grape seeds from the winemaking process!

go »

Ganimede®, thanks to the Henry's Law, is the only system that allows gases to interact deeply within the liquid mass.

go »

IYour standard tanks can be turned into innovative fermenters using Metodo Ganimede®!

Innovate and save!

go »