Home > Metodo Ganimede® > Advantages

Advantages

AdvantagesAn exclusive process part of the Metodo Ganimede®and a technology particularly suitable not only for white and rosé wines, which gain improved aroma, but also for red wines.

Only with Ganimede® the use of technical gases can be implemented scientifically, ensuring reliable and repeatable results.

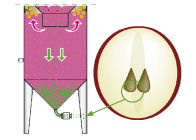

Even a cap with a thickness of more than 2.5 meters does not present a challenge: the typical "volcano restirring" process ensures full exploitation of each grape preventing compaction and formation of preferential ways of must descent. A major difference that is already evident starting from a capacity of 50 HL.

Ganimede® allows reducing processing time by about 30% compared to a traditional system under the same conditions.

All the grape seeds fall to the bottom thanks to the exclusive cap re-stirring method. Once collected at the bottom, grape seeds can be partially or totally removed from the extraction process (removal of astringent tannins), according to the winemaker's needs.

Being able to separate the seeds, the extraction involves only the cap of grape marcs, which when using Ganimede®, consists only of skins containing useful tannins in addition to coloring substances (extraction of noble substances only)

Since the overall process takes place in a controlled environment, the use of SO2 is reduced with a consequent production of healthier wines.

This is possible thanks to the perfect and complete leaching of the entire grape marc mass (the skins are always wet and thus they do not stay on the cap and/or walls and on parts of the tank that may be subject to acetic bacteria attacks).

The process is fully automated thanks to a Control Panel that allows setting all the parameters and that lets the Ganimede® fermenter work on its own, without the need for unnecessary labor.

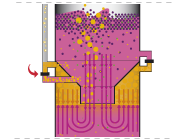

The upper jacket, placed above the diaphragm, cools the central area of the liquid, which is more distant from the outer perimeter, while the lower pocket cools the most peripheral area. The natural turbulence of the system maintains uniform temperature also near the cap.

The devatting process is quick and safe (grape marcs well-shelled and easy to extract with a standard Rotho®pump) with no extraction blades, augers and hoppers (no pressed products and by-products with high values of methyl alcohol). No risk of sudden leaks and loss of product, since the entire stage occurs in an enclosed equipment, without loss of flavor.

Ganimede® uses free energy from nature, minimizing the use of electricity! Moreover, the absence of mechanical parts reduces costs considerably, as well as it minimizes risks of technical failure and it prevents grinding of the raw material in production.

Thanks to the TOP LEVEL safety probe, in the event of a sudden increase in the level of liquid, the bypass opens automatically, allowing flooding the cavity, with a consequent lowering of the level of liquid.

The simple construction of Ganimede® makes it ideal as a storage tank featuring a unique "always full" system (by injecting inert gas below the diaphragm, the liquid is pushed upward – leading to an always-full tank).

Ganimede®, thanks to its simple construction and no mechanical parts, is easy to clean and it requires no auxiliary devices for the devatting process, preventing the difficult problem of cleaning augers and hoppers.

Reduced use of labor and full operator safety.

An EXCLUSIVE Ganimede® product designed for White and Rosé wines capable of enhancing aromas and reducing the use of sulphur dioxide in order to produce healthier wines!

go »

Metodo Ganimede® is the only fermenter in the world that allows winemakers to exclude grape seeds from the winemaking process!

go »

Ganimede®, thanks to the Henry's Law, is the only system that allows gases to interact deeply within the liquid mass.

go »

IYour standard tanks can be turned into innovative fermenters using Metodo Ganimede®!

Innovate and save!

go »