The first conversion of existing tanks in France!

TRANSLATION

Express vinifications

The Cooperative Winery La Fraternelle, in the Hérault region, is the first winery in France to have implemented its existing tanks with the Ganimede system; this process replace pump overs and délestages.

The 3rd of September 2012 the cooperative winery of Galargues et Buzignargues, in the Hérault region, receives the first grapes, a hundreds of tons of merlot. Alain Calmels, the director, and two production workers of the winery, are ready to inaugurate the Ganimede process.

Lots of wineries have purchased already brand new Ganimede vinificators but La Fraternelle winery is the very first in France to have installed the system into existinfg tanks. An investment of 150.000 euros instead of 450.000 necessary to buy 6 brand new tanks. Early last summer, the French fabricator Tecinox, welded a sort of funnel inside the tanks of 60.000 liters of the cooperative. Placed about on half height, the device uses the carbonic gas produced during the alcoholic fermentation to stirr the marc avoiding to pump over the must and délestages.

The vinification time has been halved

This process speed up the extraction of the colour and tannins. “We use it for our reds, that is 50% of our total volume” says Alain Calmels who discovered the Ganimede at Sitevi exhibition (Montpellier), last year.. “At actual stage, it represents the answer to our exigences.” From the start of the vintage, the vinification time (solid phase) has been divided in two. “We’re able to discharge the tanks after 6 days instead of 12”. Thanks to this gain of time he thinks to double the fillings of his 240.000 liters of vinification tanks. “In the past we were able to fill only two times the tanks, today we’re going towards fours fillings”.

It’s two years now the winery needs volume to vinificate. In 2009 they merged with their neighbours Boisseron. Result: the volume to vinificate grew up from 3.500.000 to 5.000.000 of liters.

“Last year we were blocked”, says Alain Calmels. “We had delayed of one week the picking up of cabernet sauvignons because the tanks were not still empty. Then we picked it up at 15-16 degrees. It was to much concentrated”. This year, a week later than merlots, he has vinificated the syrahs. “ Thanks to the fact of having the tanks empty, we had vinificate the syrah in red rather than rosé”. And he has picked up the Cabernet sauvignons on time.

Grégory Beauquier, the production responsible of the cooperative, is very excited about the tanks improvement.

Since last year, he was obliged to lose every day at least one hour and a half for each tank to do pumping over and, if necessary, even a délestage. "Our limit was of 3 délestages each tank during all the vinification process”. Today he programs his tanks in order to have the automatic mixing of the cap. The process works during the day as during the night and it’s able to obtain up to ten equal pumping over actions during 24 hours, in the first days of fermentation.

Wines more soft

“The skins are constantly wetted by the liquid” he says. “It’s less dry and this means there are less possibilities of bacteria developement”. The team state also changes during tasting. “the wines are much more rich, soft” says Alain Calmels. “The tannins are well extracted but not aggressive”. This is what the clients ask. The winery sells almost all the wines on tap (not bottled), as IGP Pays d’Oc and Herault, through its wine shop.

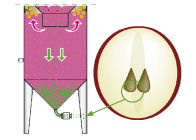

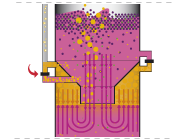

The carbon dioxide tamed to mixing the skins

A funnel of the same diameter of the tanks is fixed half way , dividing the tank in two. The carbon dioxide produced during the fermentation remains trapped under the funnel. Once the gas has completely saturated the volume under the cone, the system starts to produce a bubbling action coming from the centre (neck) of the funnel which starts to gently mix the cap. Instead of living all the gas under the funnel it is also possible to set the system in order to regularly open a couple of valves that release all the gas in the upper part of the tank causing an intense mixing of the cap. This action together with the CO2 bubbling from the center, permit to avoid délestages and pumping over. The frequency of the opening of the valve can be adjusted depending on kind of wine we want to obtain and how much we want the fermentation last.

Aside the photographs:

Alain Calmels and Gregory Beauquier (on the left), director and production responsible of the Cooperative of Galargues and Buzignargues (Hérault), are happy to have implemented their tanks with Metodo Ganimede system. In this way they can fill the tanks four times instead of only two.

This funnel inserted into the existing tanks trapped the CO2 produced during the fermentation. The gas can be exploited to regularly mix the must and the skins.

Article by Chantal Sarrazin, issued on the French revue "La Vigne", n° 246, october 2012

News & Events

News & Events